What are the Necessary Inspections before Opening the Laser Cutting Machine?

In production, we need regular maintenance and testing of laser cutting machines. In this way, we can avoid the failure during operation and ensure stable work. So what work we need to do before starting the laser cutter?

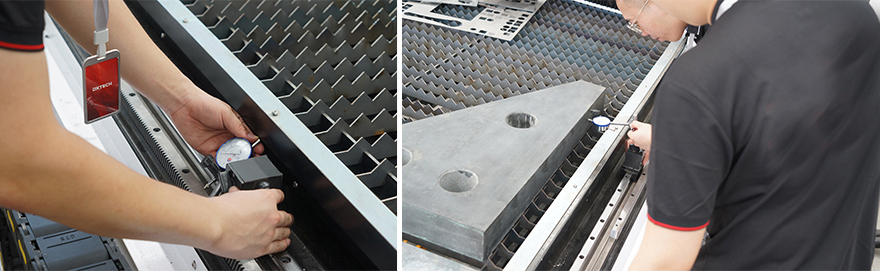

CHECK THE ENTIRE BED

Before turning on the machine, check the circuit and the casing of the whole machine. We need to check whether the power switch, voltage regulator, and auxiliary systems are working properly. Moreover, after using the laser cutting machine every day, the operator should turn off the power and clean the bed to prevent dust and residue from entering.

CHECK THE CLEANLINESS OF THE LENS

The lens of the cutting head is important to the laser cutting machine. Its cleanliness directly affects the processing performance and quality of the CNC laser cutter. If the lens is dirty, it will not only affect the cutting effect but also cause the inside of the cutting head to burn. Therefore, pre-inspection before cutting can avoid serious losses.

COAXIAL TEST OF LASER CUTTING MACHINE

The coaxially between the nozzle exit hole and the laser beam is one of the important factors affecting the cutting quality. If the nozzle and the laser are not on the same axis, the cutting effect will be affected. And seriously, the laser will hit the nozzle, causing the nozzle to heat up and burn. In addition, the operator needs to check whether the air pipe joints are loose and whether the pipe belt is damaged. Tighten or replace them if necessary.

CHECK THE STATUS OF THE LASER CUTTING MACHINE CHILLER

Check the overall condition of the chiller. We need to deal with problems such as dust accumulation, pipe blockage, and insufficient cooling water in time. Regular dust removal and replacement of circulating water can ensure the operation of the equipment.

CONCLUSION

Before starting the CNC laser cutter, we must check the condition of each component in time. If you find that there is a problem with the parts on the machine, you must solve it in time. This ensures the normal operation of the machine and prolongs its service life.

MAMTECHNIC has been established for more than 20 years. We adhere to professional design principles. In the future, we will continue to develop domestic and foreign markets and build a more professional brand.